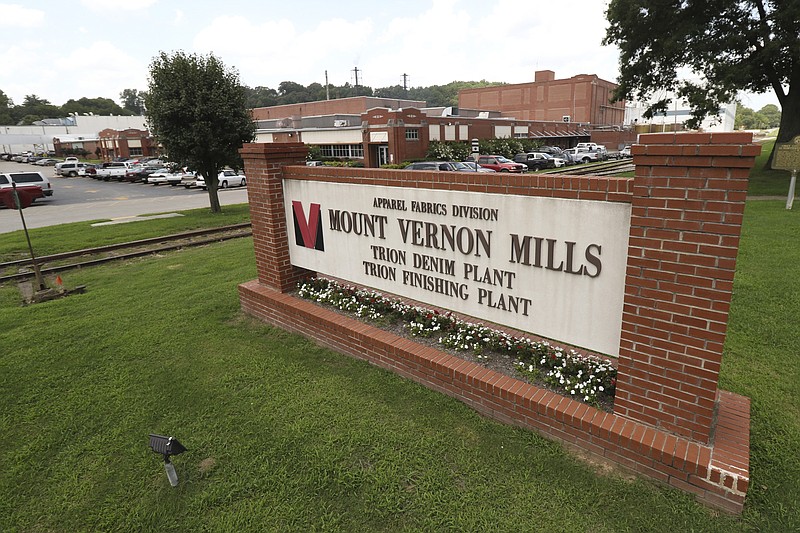

Mount Vernon Mills, a 180-year-old textile company based in Trion, Georgia, is spearheading an ambitious initiative to revive industrial-scale American selvedge denim production. The company recently secured the celebrated Draper X3 “shuttle” looms—once operated at the famed Cone Mills White Oak Plant in Greensboro, North Carolina—after the closure of that facility in 2017 marked the end of large-scale selvedge weaving in the U.S.

Selvedge (also spelled selvage) refers to denim — or any woven fabric — that is made on old-style shuttle looms, which produce a tightly woven, self-finished edge that prevents the fabric from unraveling.

In simple terms

Selvedge denim = premium denim woven the traditional way, with a clean finished edge.

These narrow shuttle looms produce fabric with a distinctive character—slower, narrower and more textured than modern looms, delivering the iconic selvedge edge prized by high-end denim aficionados. After White Oak shut down, the looms went to Vidalia Mills in Louisiana, which ultimately collapsed in 2024 under more than $30 million in debt, leaving the future of American selvedge uncertain.

Now Mount Vernon Mills, already a major denim supplier to brands like Levi’s and Carhartt, has reached an agreement with KaKa Cotton to move the looms to its Trion, Georgia facility. The goal is to launch the first American industrial-scale selvedge production line since White Oak’s closure. President Bill Rogers says the company has the “viable denim business” foundation to make this work—not banking solely on selvedge—but sees the revival as both culturally significant and commercially viable.

To bring the old looms back online, Mount Vernon Mills is sourcing spare parts from old mills and warehouses, recruiting expertise from heritage textile groups, and forming strategic partnerships to train operators. If all goes according to plan, the first single-shift selvedge production line could be running by spring 2026.

Industry experts say the move could mark a turning point for U.S. textile craftsmanship. “These looms are a national treasure,” says co-founder of Raleigh Denim, Victor Lytvinenko, noting that Mount Vernon Mills is likely the only facility in the U.S. truly capable of operating them at scale. While the look may differ slightly from the original White Oak output—owing to differences in factory floor vibration and setup—the revival effort signals hope for the return of authentic American-made selvedge denim.

With 180 years of history and a facility built with the flexible wood floors ideal for shuttle looms, Mount Vernon Mills is uniquely positioned to handle the production. The company also controls every component of denim manufacturing—from indigo dyeing and finishing to yarn production.

Mount Vernon’s press release:

Mount Vernon Mills, a cornerstone of American textile manufacturing, is proud to announce a strategic partnership with KaKa Cotton, LLC to acquire and relocate 45 historic Draper X3 shuttle looms originally operated at the iconic White Oak Plant in Greensboro, North Carolina.

These looms, renowned for producing some of the finest selvedge denim in the world, will find a new home at Mount Vernon Mills’ flagship facility in Trion, Georgia. The move marks a significant step toward reviving traditional American denim craftsmanship and preserving a vital piece of textile history.

In addition to the Draper X3 looms, Mount Vernon Mills is also acquiring 45 Picanol President shuttle looms to further expand its selvedge denim weaving capacity. This combined investment underscores the company’s commitment to meeting growing demand for authentic, U.S.-made selvedge denim.

The announcement comes as Mount Vernon Mills celebrates its 180th anniversary, reinforcing its legacy as one of the longest-standing textile manufacturers in the United States.

“We are honored to carry forward the legacy of American selvedge denim craftsmanship,” said Bill Rogers, President of Mount Vernon Mills. “This partnership with KaKa Cotton allows us to blend heritage with innovation, and we’re excited about the opportunities it brings for our community, our customers, and the broader U.S. textile industry. This is more than a business decision — it’s a commitment to American manufacturing and the enduring spirit of American textile excellence.”

The relocation effort follows the recent closure of Vidalia Mills, which had previously operated the Draper X3 looms. With the facility shuttered, Mount Vernon Mills and KaKa Cotton acted swiftly to ensure these iconic machines remain in operation on American soil.

The looms will be restored and integrated into a dedicated production line focused on premium selvedge denim, with operations expected to begin in early 2026. The initiative is also expected to create new skilled jobs in Trion and attract interest from denim enthusiasts and heritage brands seeking authentic, U.S.-made fabric.

Read more here: Mount Vernon Mills Acquires Historic White Oak Shuttle Looms

Chattooga Lifestyle

DAISY Award goes to two nurses at AdventHealth Gordon

Chattooga Schools

Floyd County: FAME Students Learn on Location with Rome Fire Department

Bulloch Public Safety

01/12/2026 Booking Report for Bulloch County

Bulloch Public Safety

01/01/2026 Booking Report for Bulloch County

Bulloch Public Safety

12/29/2025 Booking Report for Bulloch County

Bulloch Public Safety

01/20/2026 Booking Report for Bulloch County

Bulloch Public Safety

01/09/2026 Booking Report for Bulloch County